SPRING HANGERS

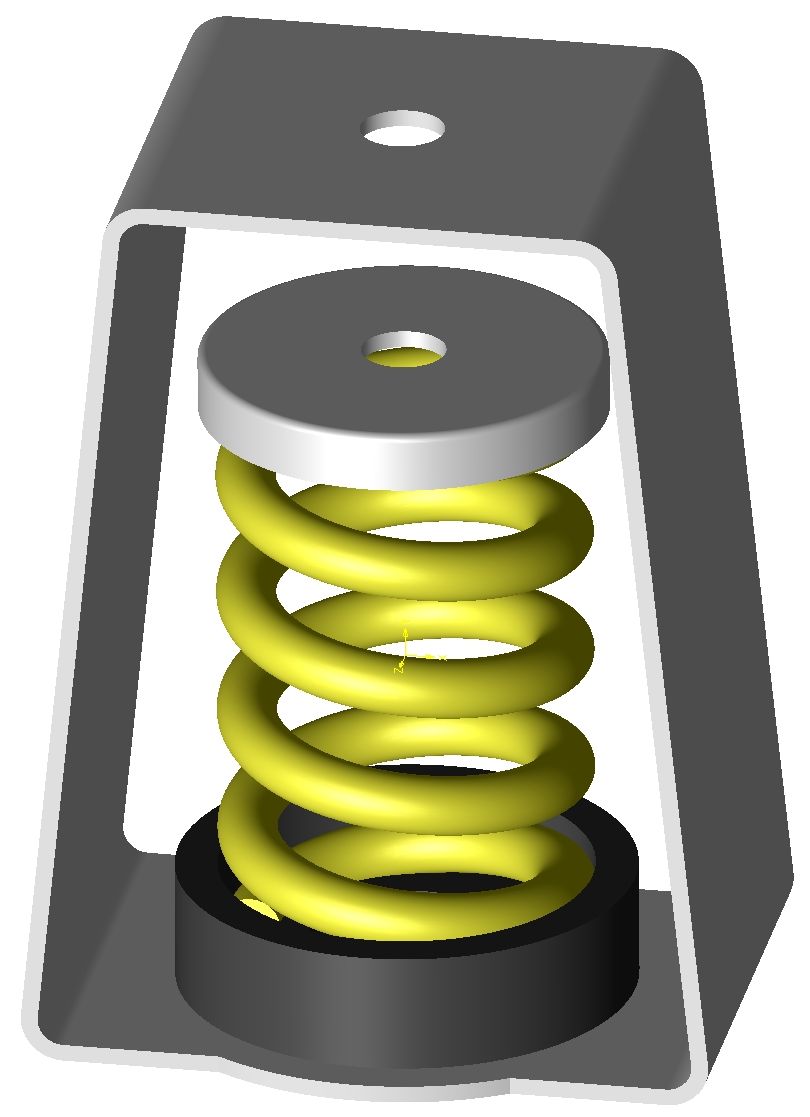

Spring Hangers

We provide top-quality spring hanger solutions designed to eliminate vibration and noise in various mechanical and acoustic applications. Our spring hangers are made for durability and efficiency and can handle heavy loads of up to 950 kg. They are ideal for applications where vibration isolation and reducing noise is crucial, ensuring effective isolation and noise control.

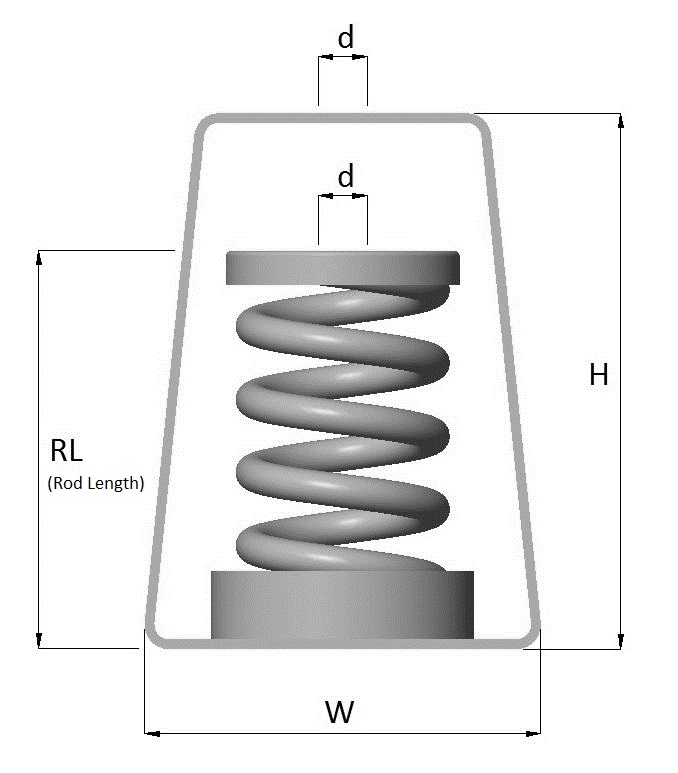

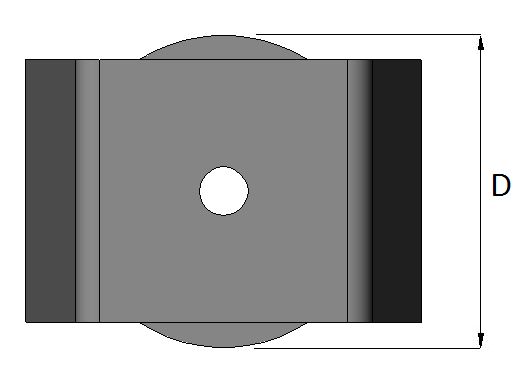

| Size | Rated Load (kg) | Rated Defl. (mm) | Spring Rate (kg/mm) | Spring Colour | H | D | RL | d | W |

|---|---|---|---|---|---|---|---|---|---|

| SH1 - 45 | 20 | 40 | 0.5 | Blue | |||||

| 75 | 34 | 38 | 0.9 | Orange | |||||

| 125 | 56 | 33 | 1.7 | Red | 130 | 50 | 100 | 10 | 83 |

| 200 | 90 | 29 | 3.1 | Black | |||||

| 310 | 150 | 25 | 6.1 | Yellow | |||||

| SH2 - 60 | 27 | 54 | 0.5 | Grey | |||||

| 140 | 64 | 49 | 1.3 | Orange | |||||

| 280 | 128 | 40 | 3.2 | Green | 180 | 65 | 135 | 12 | 120 |

| 450 | 207 | 33 | 6.3 | Red | |||||

| 750 | 340 | 30 | 11.3 | White | |||||

| 1000 | 450 | 25 | 18 | Blue | |||||

| SH3 - 225 | 100 | 45 | 2.2 | Blue | |||||

| 435 | 200 | 39 | 5.1 | Grey | |||||

| 735 | 320 | 35 | 9.2 | White | 190 | 75 | 140 | 16 | 135 |

| 1000 | 445 | 26 | 17.2 | Black | |||||

| 1350 | 615 | 25 | 24.6 | Yellow | |||||

| 1675 | 765 | 25 | 30.6 | Yellow* | |||||

| 2100 | 950 | 25 | 38 | Yellow** |

* Tolerance on Brackets ±5mm

Why Choose Seal 'N Devices Spring Hangers?

Our spring hangers are designed to meet the highest industry standards, offering unparalleled durability and reliability. Here’s why our solutions are trusted in industrial, sound, and HVAC applications across various sectors:

- Load Handling Capacity: Our spring hangers can support loads up to 950 kg, making them suitable for a wide range of applications, from lightweight air ducts or pipework to heavier equipment such as fans..

- Vibration Isolation: Our Spring hangers are designed to reduce the transmission of vibration and noise produced by suspended equipment and piping.Durability: Constructed from high-quality materials, Seal ‘N Devices spring hangers are engineered to withstand harsh industrial environments and maintain optimal performance over time.

- Custom Solutions: We offer various sizes and configurations to meet the specific needs of various HVAC equipment, silencers, air ducts, compressors, fans as well as suspended ceilings, Ensuring you get the perfect solution for your application

Applications of Spring Hangers

Our spring hangers are ideal to reduce the transmission of vibration and noise by suspended equipment and piping. Solutions including:

- HVAC Systems: Spring hangers are commonly used in heating, ventilation, and air conditioning (HVAC) systems to minimise noise and vibration from equipment like fans, compressors, and pumps.

- Ductwork and Piping: One of the primary uses for spring hangers is in vibration isolation for suspended ductwork and piping systems. These hangers ensure that noise and vibrations from pipes and ducts do not transmit into the building structure, which is particularly useful in noise-sensitive environments. Spring hangers reduce vibration and stress on pipes, preventing damage and extending the system’s life.

- Ceiling Suspension Systems: Spring hangers are used for suspended ceilings for floating drywall ceilings systems designed to reduce noise . In such cases, Spring Hangers help achieve significant reductions in sound transmission, especially at low frequencies.

- Anti Vibration Machine hanging: From industrial motors, pumps or compressors, our spring hangers can be integrated into various types of machinery to reduce the transfer of noise and vibration

Benefits of Using Spring Hangers

- Enhanced Equipment Lifespan: Reducing the impact of vibrations prolongs the operational life of machinery, minimising maintenance and repair costs.

- Improved Workplace Comfort: By isolating noise and vibrations, spring hangers help create a quieter and more comfortable environment, which is particularly important in factories or commercial buildings.

- Increased Efficiency: Equipment that operates with reduced vibration tends to perform more efficiently, reducing wear and tear and optimising energy consumption.

Custom Spring Hanger Solutions

Seal ‘N Devices understands that each setup is unique, so we offer customised spring hanger solutions tailored to your specific needs. Our team of experts is ready to assist you in selecting the correct spring hanger configuration for your application, ensuring optimal vibration and noise control and load-bearing capacity.

Contact Seal ‘N Devices for Details

If you’re looking for a reliable solution to control vibration and noise in your industrial operations, Seal ‘N Devices has the perfect spring hanger options for you.

Contact us today to learn more about our spring hangers and how they can benefit your business.