MUSHROOM

MOUNTS

Mushroom Mounts

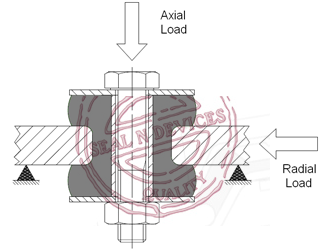

Seal ‘N Devices’ anti-vibration mushroom mounts, also known as two-piece rubber mounts or simply universal anti-vibration mountings, provide a simple yet highly effective solution for vibration isolation across a wide range of industries and equipment types. Designed for durability and performance, they efficiently absorb vibration and shock in both axial and radial directions, making them ideal for dynamic environments.

Whether you are looking to extend the service life of machinery, improve comfort in mobile equipment, or protect sensitive systems, our anti-vibration mushroom mounts offer a failsafe design that combines reliability with cost-efficiency.

Why Choose Seal ‘n Devices’ Mushroom Mounts?

- Failsafe Design: Two-piece rubber mounts are engineered to remain secure under extreme operating conditions, even in the event of rubber failure.

- Multi-Directional Load Handling: Performs effectively under both axial (vertical) and radial (horizontal) loads for maximum vibration control.

- Cost-Effective Solution: Universal mountings that deliver long-lasting vibration isolation without the high cost of complex suspension systems.

- Simple Installation: Compact and adaptable design allows for quick and flexible installation of the anti-vibration mushroom mounts across various machine types and structures.

- Customisable: We can produce our anti-vibration mushroom mounts in various compounds, including natural rubber, neoprene rubber, EPDM, nitrile and various other compounds.

Applications for Anti-Vibration Mushroom Mounts

Our two-piece mushroom mounts are trusted across multiple industries due to their versatility and rugged performance. Common applications include:

- Highway and Off-Highway Vehicles: Minimise vibration transmission from engines and suspension systems to improve durability and operator comfort.

- Generators and Compressors: Isolate vibrations to protect internal components, reduce noise, and prevent structural fatigue.

- Ant-Vibration Cabin Mounts: Ideal for a wide array of machinery.

- Pumps and Centrifuges: Maintain smooth operation and reduce wear by absorbing continuous rotational and pulsating vibrations.

- Marine Equipment and Power Plants: Withstand harsh marine environments and offer reliable support for heavy, high-performance engines and auxiliary systems.

- Radiator Mountings: Provide cushioning and vibration damping to prolong radiator life and ensure consistent cooling performance.

- HVAC Equipment: Reduce noise and vibration transmission in heating, ventilation, and air conditioning (HVAC) systems for enhanced indoor comfort.

Note to dev: Please insert the product table here.

Built for Demanding Environments

Seal ‘N Devices’ anti-vibration mushroom mounts are made from quality natural or synthetic rubber and robust metal components, ensuring exceptional performance in demanding industrial, mobile, and marine environments. Their compact footprint makes them suitable for both OEM applications and retrofit installations.

Choosing the correct vibration mount is essential to machinery performance and lifespan. Our technical experts can guide you through product selection, custom solutions, and technical specifications.

Contact us today for expert guidance and product recommendations.

Description

Our Mushroom mountings or universal mountings are a simple yet cost effective method of isolating vibration efficiently with the benefits of a failsafe design. The Mushroom Mounts perform effectively under both Axial and Radial loads.

Applications:

- Highway and off-highway vehicles

- Generators & Compressors

- Pumps and Centrifuges

- Marine Equipment & Power Plants

- Radiator Mountings

- HVAC Equipment

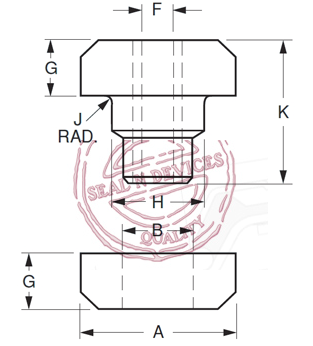

| MUSHROOM MOUNTS | ||||||||||

| PART No | A (mm) | B (mm) | F (mm) | G (mm) | H (mm) | K (mm) | J (mm) | Axial Load (N) | Radial Load (N) | Plate Thickness (mm) |

| MSH1-45 | 34 | 15 | 10 | 12 | 20 | 32 | 1 | 260 | 130 | 10mm |

| MSH1-60 | 34 | 15 | 10 | 12 | 20 | 32 | 1 | 530 | 170 | 10mm |

| MSH2-45 | 50 | 20 | 13 | 20 | 32 | 50 | 1,5 | 650 | 250 | 12mm |

| MSH2-60 | 50 | 20 | 13 | 20 | 32 | 50 | 1,5 | 1250 | 500 | 12mm |

| MSH3-45 | 65 | 26 | 16 | 23 | 40 | 62 | 2,3 | 1550 | 600 | 20mm |

| MSH3-60 | 65 | 26 | 16 | 23 | 40 | 62 | 2,3 | 3100 | 1300 | 20mm |

| MSH4-45 | 89 | 35 | 24 | 25 | 58 | 73 | 3 | 2200 | 880 | 25mm |

| MSH4-60 | 89 | 35 | 24 | 25 | 58 | 73 | 3 | 4400 | 1750 | 25mm |

| MSH5-45 | 125 | 47 | 27 | 27 | 64 | 85 | 3 | 5700 | 2100 | 32mm |

| MSH5-60 | 125 | 47 | 27 | 27 | 64 | 85 | 3 | 11500 | 4400 | 32mm |