CRANE BUFFER /HEAVY DUTY BUFFERS

Crane Buffers

Crane buffers are an essential safety and performance component for industrial cranes. They can also be referred to as rubber buffers, EOT crane buffers, overhead crane buffers, end buffers, buffer stops or crane rubber buffers. They are designed to absorb maximum energy and protect the crane and surrounding structures from impact forces. Our high-quality rubber crane buffers are built to withstand intense loads, minimise wear and tear, and enhance operational safety in demanding environments.

Whether you’re operating overhead cranes, gantry cranes, or other heavy machinery or hoisting equipment, our rubber crane buffers ensure optimal energy absorption and long-term reliability.

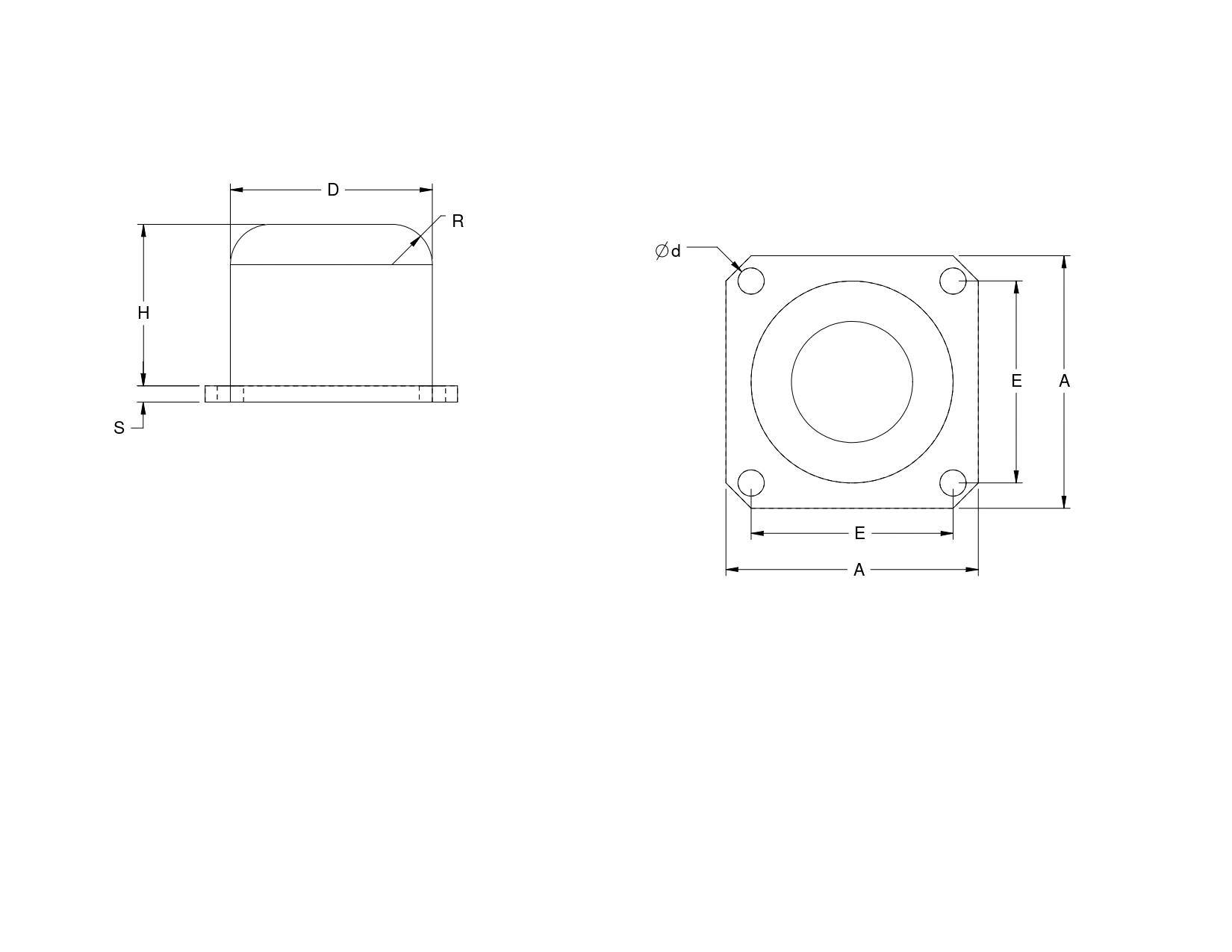

Rubber Buffer Specifications

| Part Number | D (mm) | A (mm) | d (mm) | E (mm) | H (mm) | R (mm) | S (mm) | Wmax (J) | F (kN) | Defl (mm) | W (kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| CRA001 | 80 | 100 | 11 | 80 | 63 | 16 | 6 | 400 | 40 | 32 | 0.88 |

| CRA002 | 100 | 125 | 13 | 100 | 80 | 20 | 8 | 800 | 63 | 40 | 1.82 |

| CRA003 | 125 | 160 | 17 | 125 | 100 | 25 | 8 | 1600 | 100 | 50 | 3.25 |

| CRA004 | 160 | 200 | 17 | 160 | 125 | 32 | 10 | 3200 | 160 | 63 | 6.50 |

| CRA005 | 200 | 250 | 21 | 200 | 160 | 40 | 10 | 6300 | 250 | 80 | 11.30 |

| CRA006 | 250 | 315 | 21 | 250 | 200 | 50 | 12 | 12500 | 400 | 100 | 22.60 |

| CRA007 | 315 | 400 | 21 | 315 | 250 | 63 | 12 | 25000 | 630 | 125 | 41.20 |

** Also available with circular base and stud. Please enquire.

Wmax(J) = Maximum energy that the buffer can absorb.

F(kN) = Maximum force that the buffer can withstand.

Why Choose Our Crane Buffers?

Our crane buffers stand out for their superior performance and robust design. Here’s why they’re the perfect solution for your industrial needs:

- Maximum Energy Absorption: Engineered to handle high-energy impacts, our Crane buffers efficiently dissipate force to prevent damage.

- Durability Under High Forces: Manufactured from high-quality natural or synthetic rubber, our crane buffers are designed to withstand heavy loads and repetitive use.

- Reliable Performance: Provides consistent protection to enhance the lifespan of cranes and reduce maintenance costs.

- Wide Compatibility: Suitable for multiple crane types, including overhead cranes, gantry cranes, and other industrial lifting equipment.

Key Features of Our Crane Buffers

- Energy Absorption: Designed to dissipate maximum impact energy.

- High Force Resistance: Built to withstand intense and repetitive forces.

- Durable Materials: Manufactured with high-grade rubber and steel.

- Low Maintenance: Reduces downtime and overall maintenance costs.

Types of Rubber Crane Buffers

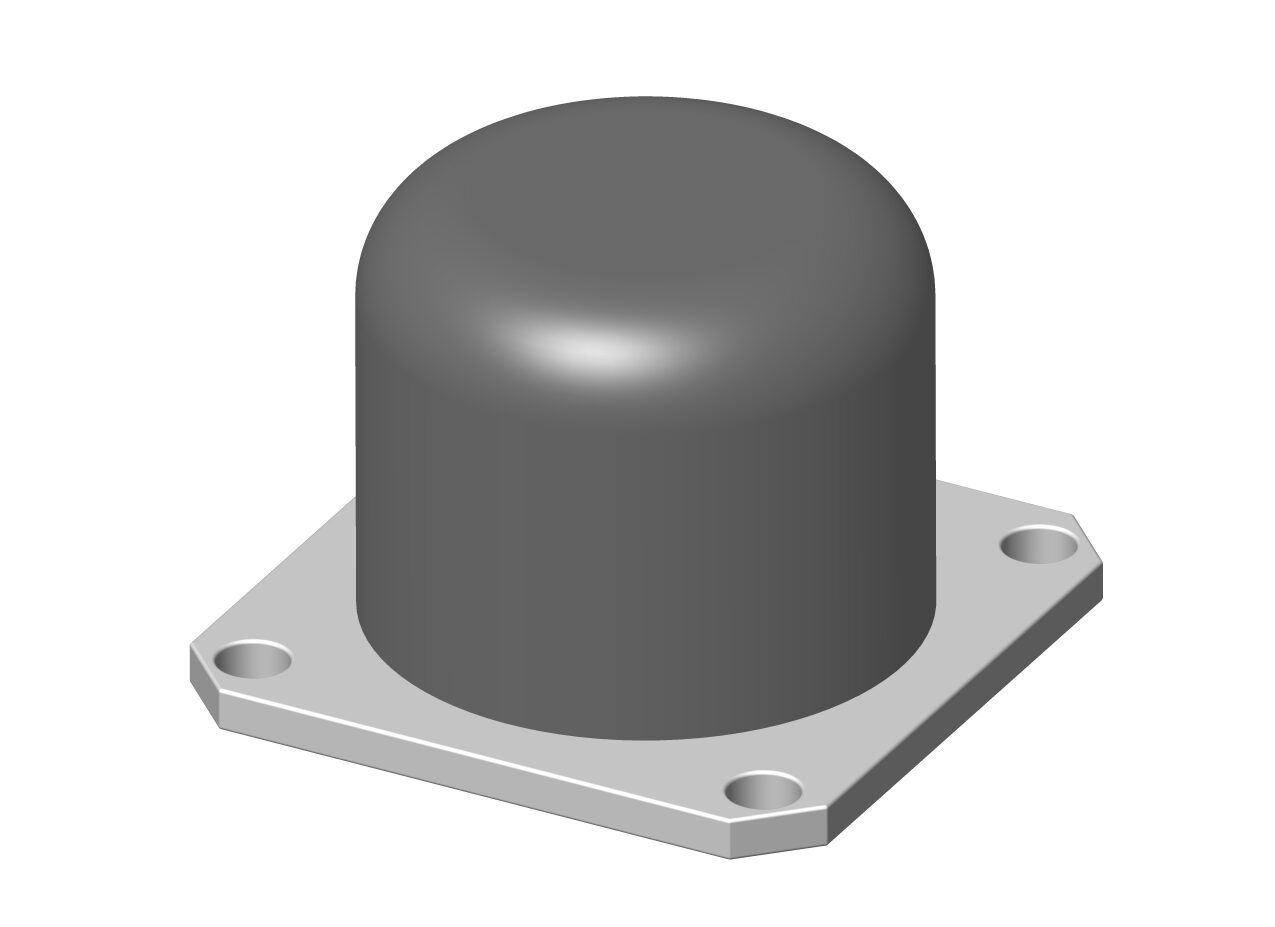

- Cylindrical Rubber Buffer – Available with square mounting plate as well as a round plate with a threaded stud for mounting.

- Rectangular or Square plate Rubber Buffers: Provide a wider surface are.

- Bolt on Rubber Buffers with Steel bracket – Designed for easy installation.

- Custom Crane Buffers or Custom Material can be used to suit your application.

Applications of Rubber Crane Buffers

Rubber crane buffers are commonly installed in various industrial and material handling environments, including:

- Overhead cranes

- Gantry and portal cranes

- Electric overhead travelling (EOT) cranes

- Hoists and lift systems.

Whether for light-duty applications or heavy duty lifting equipment, our rubber crane buffers provide consistent energy absorption.

Order Crane Buffers from Seal' n Devices Today!

Contact us today to learn more about our products or request a quote for your specific needs. Let Seal’ n Devices deliver the durable and innovative solutions your industry demands.